Differential pressure measurement is widely used in domestic and industrial applications. It is often the basis for other measurements such as flow, level, density, viscosity and even temperature. The most common are level and flow.

Flow measurement is one of the most common applications for differential pressure transmitters. By measuring the difference in fluid pressure as the fluid flows through a tube, it is possible to calculate the flow rate.

Differential pressure flow meters have a primary and a secondary element. In general, the primary element is designed to produce a pressure difference as the flow increases. There are many different types of primary elements, the most common being the orifice plate, flow nozzle and pitot tube.

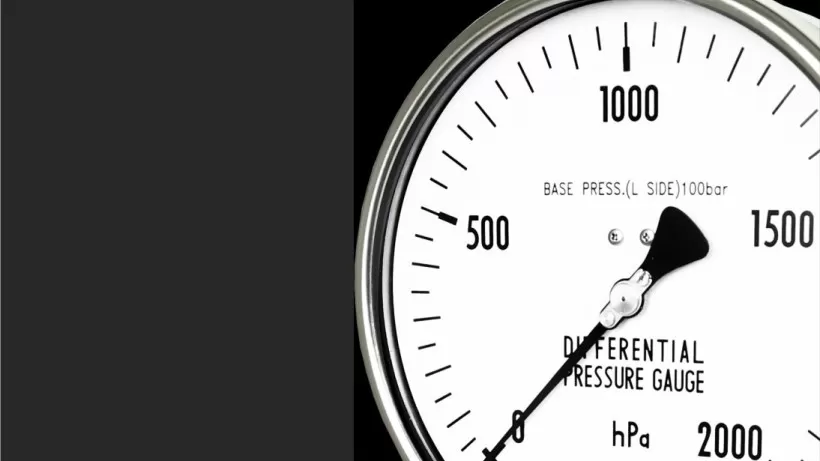

The secondary element of the flow meter is the differential pressure transmitter. It is designed to measure the differential pressure produced by the primary element as accurately as possible. In particular, it is important that the differential pressure measurement is not affected by changes in fluid pressure, temperature or other properties, such as ambient temperature.

A good differential pressure transmitter will ensure that the differential pressure is accurately measured independent of other variable parameters and will reliably transmit a signal to represent the differential pressure. In the case of a differential pressure flow transmitter, the output signal can also include square root extraction. Although it is common nowadays this function is carried on a Dcs system flow computer.