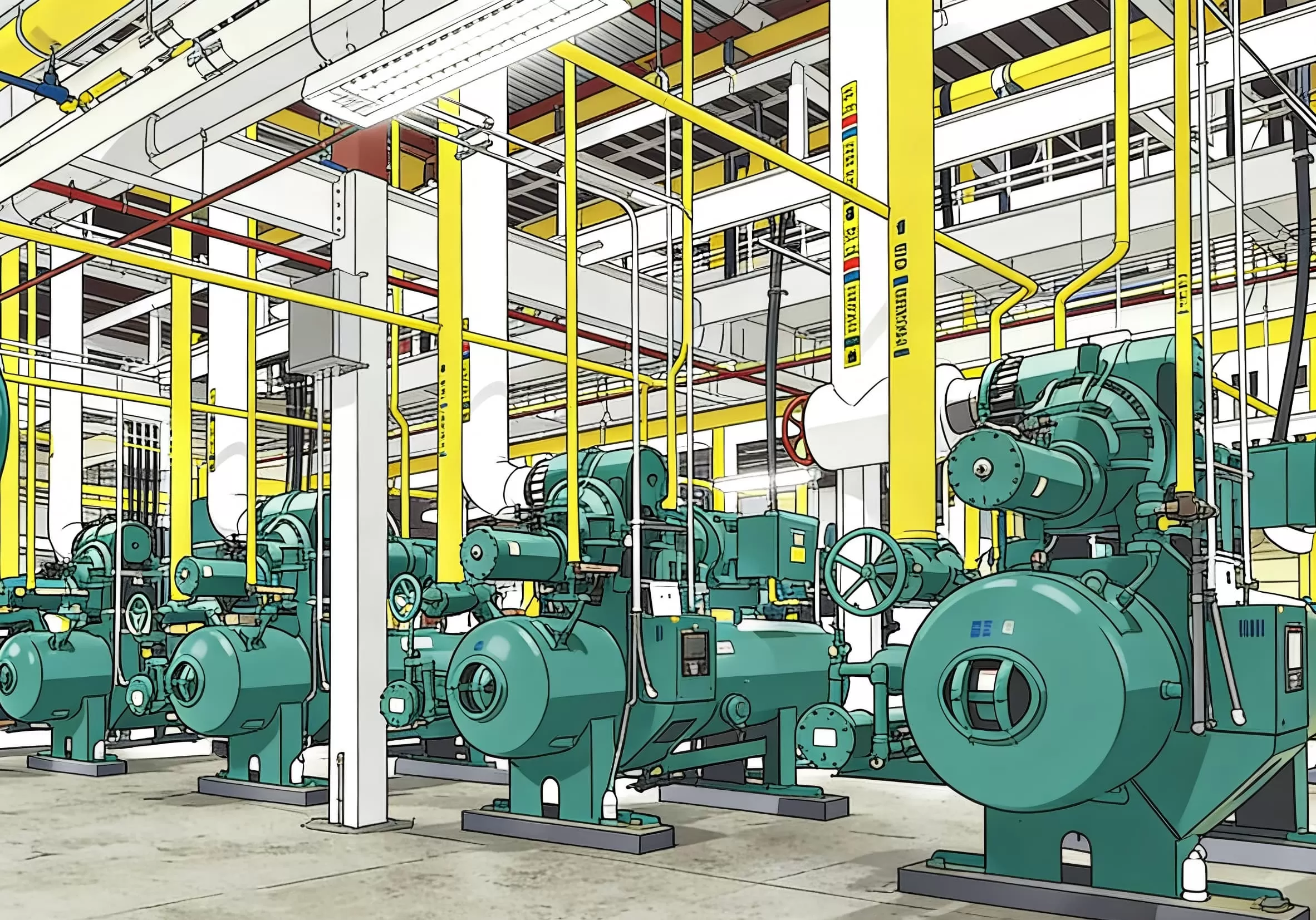

Refrigeration systems are fundamentally governed by pressure. From the moment a compressor starts, system stability, cooling capacity, energy efficiency, and equipment safety all depend on maintaining pressure within precisely defined operating windows. Whether in industrial cold storage, food processing, pharmaceutical refrigeration, chemical cooling processes, or commercial refrigeration equipment, pressure is the primary variable that directly reflects system health.

Within this context, refrigeration pressure switches and refrigeration pressure transmitters (pressure sensors) form the core of monitoring, protection, and control architecture. While temperature defines the refrigeration objective, pressure determines whether the system can safely and efficiently achieve that objective.

Pressure switches are indispensable safety components in refrigeration systems. Their primary role is to provide immediate, hardware-level protection independent of software logic or network communication.

High-pressure switches are typically installed on the compressor discharge line. Their functions include:

- Preventing compressor damage caused by condenser fouling, fan failure, or high ambient temperatures.

- Protecting piping, valves, and heat exchangers from overpressure.

- Ensuring compliance with refrigeration safety standards and equipment certifications.

In industrial refrigeration plants operating with ammonia, CO₂, or other high-pressure refrigerants, high-pressure switches are mandatory safety devices. When discharge pressure exceeds a preset limit, the switch instantly shuts down the compressor, preventing catastrophic failure.

Low-pressure switches are usually installed on the suction side of the compressor. They serve multiple purposes:

- Protecting compressors from refrigerant loss or leakage.

- Preventing operation under insufficient evaporator pressure, which can cause overheating and lubrication failure.

- Acting as a control input for pump-down cycles and defrost sequences.

In cold storage and commercial refrigeration, low-pressure switches are often used to stop compressors when cooling demand is satisfied, enabling simple and reliable on–off control strategies.

Despite the widespread adoption of digital control systems, pressure switches remain irreplaceable because they provide:

- Immediate response without signal processing delay.

- High reliability in harsh refrigeration environments.

- Redundant protection independent of PLCs or controllers.

In many refrigeration projects, pressure switches are legally required as part of the safety architecture.

While pressure switches protect systems from extreme conditions, **pressure transmitters** enable continuous measurement and intelligent control.

Pressure transmitters provide real-time analog or digital signals representing system pressure. Typical applications include:

- Compressor suction and discharge pressure monitoring.

- Condensing pressure optimization in air-cooled and water-cooled condensers.

- Evaporator pressure control for accurate temperature regulation.

By converting pressure into a continuous signal, pressure transmitters allow refrigeration controllers to make precise adjustments rather than relying on simple on-off logic.

Pressure transmitters are essential for modern energy-saving refrigeration techniques, such as:

- Floating head pressure control-, where condensing pressure is dynamically adjusted based on ambient conditions.

- Variable-speed compressor control-, enabling smooth capacity modulation.

- Early fault detection, identifying abnormal pressure trends before alarms or shutdowns occur.

In large industrial refrigeration systems, even small improvements in pressure control translate directly into significant energy savings over continuous operation.

Refrigeration environments expose sensors to vibration, oil contamination, temperature extremes, and pressure pulsation. High-quality refrigeration pressure transmitters are designed to deliver:

- Long-term signal stability.

- High resistance to refrigerant media.

- Reliable performance under continuous operation.

This reliability is critical for cold chain applications where system downtime can lead to severe economic losses.

In refrigeration systems, pressure switches and pressure transmitters are not alternatives—they are complementary.

- Pressure switches provide hardwired, fail-safe protection.

- Pressure transmitters enable intelligent control, optimization, and diagnostics.

A well-designed refrigeration system typically uses both:

- Pressure switches for emergency shutdown and safety compliance.

- Pressure transmitters for continuous monitoring, efficiency improvement, and predictive maintenance.

Together, they form a layered protection and control strategy that balances safety, performance, and operational efficiency.

The combined use of pressure switches and pressure transmitters delivers substantial value across refrigeration applications:

- Industrial refrigeration plants benefit from improved safety and energy efficiency.

- Commercial refrigeration gains reliable compressor protection and simplified control.

- Pharmaceutical refrigeration meets stringent regulatory and traceability requirements.

For refrigeration-focused projects, the most critical product categories include:

- Refrigeration pressure switches for high- and low-pressure protection

- Refrigeration pressure transmitters for continuous monitoring and optimization

In refrigeration systems, pressure defines safety, efficiency, and reliability. Refrigeration pressure switches provide the essential mechanical protection that prevents catastrophic failures, while refrigeration pressure transmitters unlock intelligent control strategies that reduce energy consumption and extend equipment life. Supporting these core components.

As refrigeration systems continue to scale in size, complexity, and regulatory scrutiny, the role of these sensing and protection technologies becomes increasingly central. They do not simply support refrigeration operation—they determine its success.