Cleanrooms are highly controlled environments designed to minimize airborne particles, regulate pressure differentials, and maintain strict temperature and humidity conditions. They are essential across industries such as pharmaceuticals, biotechnology, medical devices, semiconductors, electronics manufacturing, and advanced laboratories. In these environments, even microscopic deviations in airflow balance, pressure stability, or humidity control can lead to product contamination, yield loss, regulatory non-compliance, or safety risks.

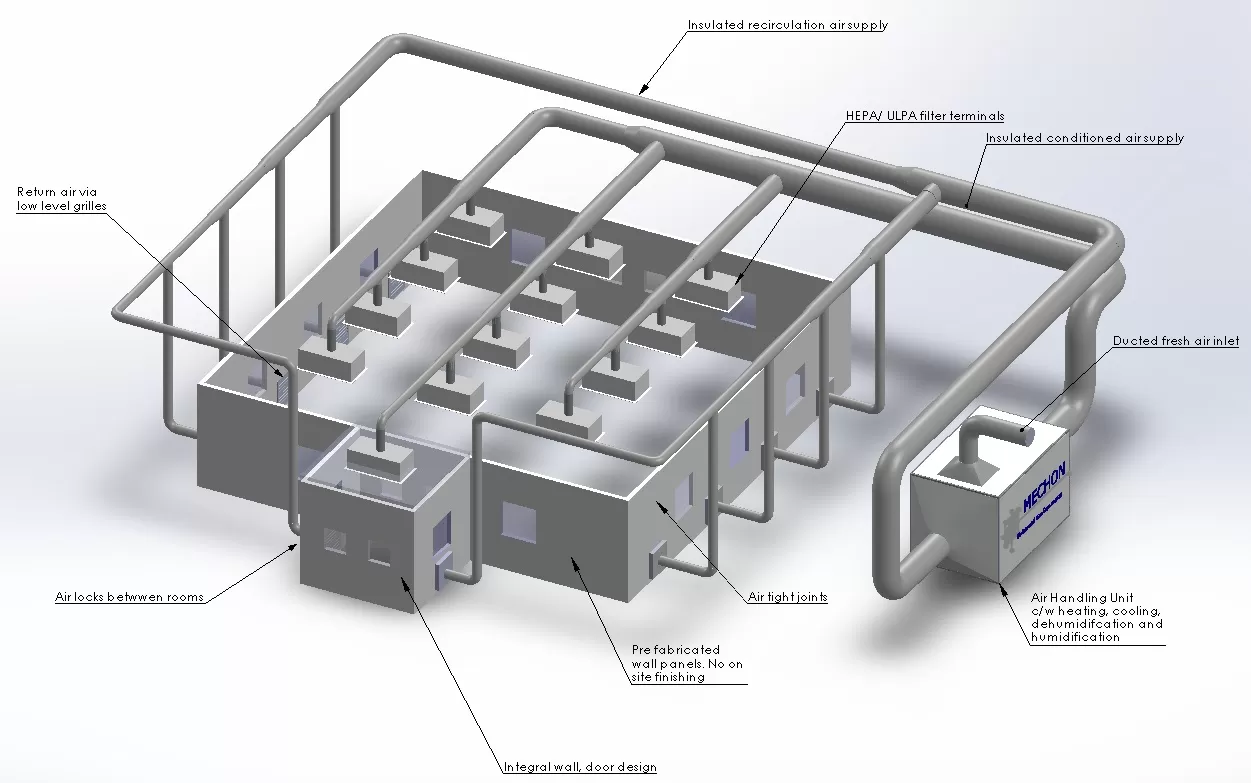

Unlike conventional HVAC systems, cleanroom infrastructure must operate continuously with exceptional stability, redundancy, and accuracy. This places elevated demands on fluid handling equipment, environmental sensors, and pressure monitoring devices. Products such as Differential Pressure Transmitters, Pressure Transmitters, Temperature & Humidity Transmitters, Environmental Transmitters, BLDC Circulation Pumps, Diaphragm Booster Pumps, Peristaltic Pumps, Flowmeters, and Pressure Switches form the backbone of cleanroom environmental control and validation systems.

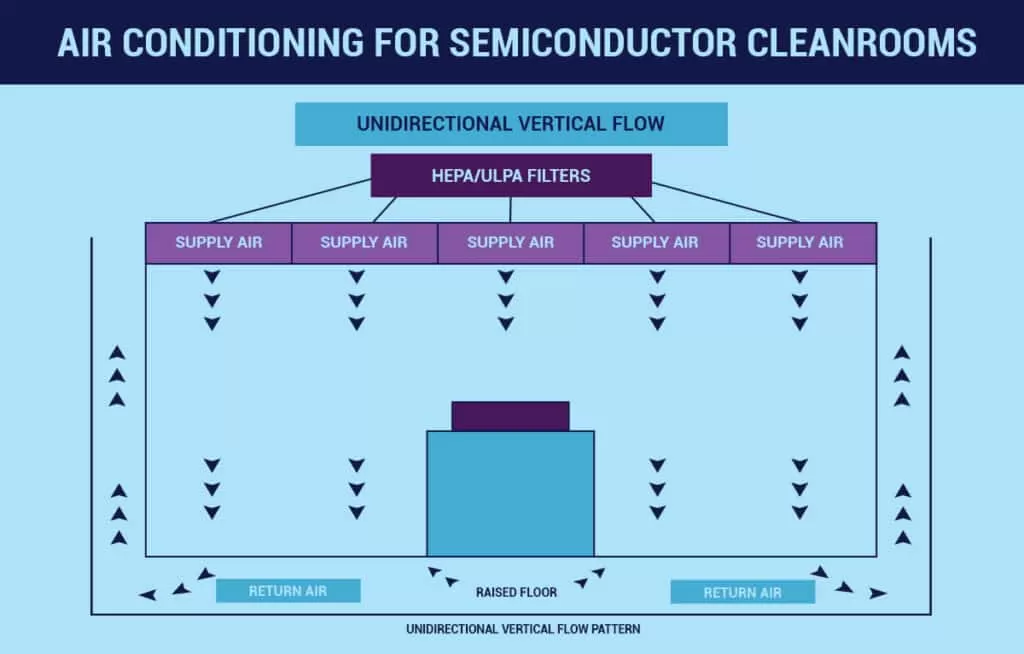

Among all cleanroom parameters, pressure control is arguably the most critical. Cleanrooms rely on pressure cascades—positive pressure to prevent external contamination or negative pressure to contain hazardous substances.

Differential Pressure Transmitters are indispensable in this context. They continuously measure pressure differences between adjacent rooms, airlocks, corridors, and process zones. Their applications include:

- Monitoring pressure differentials between cleanroom grades (e.g., ISO Class 5 to ISO Class 7).

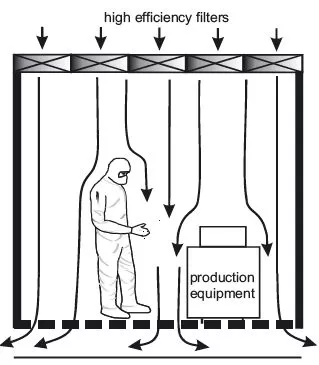

- Controlling supply and exhaust airflow to maintain unidirectional airflow patterns.

- Triggering alarms when pressure falls outside validated thresholds.

High-accuracy differential pressure transmitters ensure compliance with GMP, ISO 14644, and FDA requirements. Their long-term stability minimizes recalibration frequency, which is essential in validated environments where system downtime is costly.

Pressure Switches often complement transmitters by providing redundant safety interlocks, ensuring immediate response to abnormal pressure loss and protecting both personnel and sensitive products.

Cleanroom processes are highly sensitive to temperature and humidity variations. In pharmaceutical and semiconductor environments, even slight humidity deviations can affect chemical reactions, material properties, electrostatic discharge risks, and microbial growth.

Temperature & Humidity Transmitters are deployed in multiple locations, including:

- Supply and return air ducts.

- Critical process zones.

- Equipment enclosures and pass-through chambers.

These devices provide continuous, high-resolution data to building management systems (BMS) and cleanroom monitoring software. Their advantages include:

- Accurate humidity control to prevent condensation or electrostatic discharge.

- Stable temperature regulation for process repeatability.

- Support for environmental data logging required during audits and validations.

Environmental Transmitters, which combine multiple sensing parameters, further enhance system integration by reducing installation complexity and improving data consistency across the cleanroom.

While airflow is the visible hallmark of cleanrooms, fluid circulation systems operate quietly in the background to sustain environmental stability.

BLDC Circulation Pumps are widely used in chilled water and hot water loops serving air handling units (AHUs), fan filter units (FFUs), and dehumidification systems. Their variable-speed capability enables precise temperature control while significantly reducing energy consumption—an important consideration given the continuous operation of cleanrooms.

Key benefits include:

- High efficiency under partial load conditions.

- Low vibration and noise, supporting sensitive environments.

- Long service life with reduced maintenance requirements.

In localized applications such as humidification systems, condensate handling, or purified water circulation, Diaphragm Booster Pumps (115V or 230V) provide reliable pressure boosting and stable flow under intermittent operation. Their ability to handle air-liquid mixtures and pressure fluctuations makes them particularly suitable for cleanroom auxiliary systems.

Cleanroom facilities often incorporate sophisticated water treatment systems for humidification, cleaning processes, and utility support. Maintaining water quality is essential to prevent contamination and corrosion.

Peristaltic Pumps play a crucial role in:

- Precise chemical dosing for water treatment systems.

- Biocide and corrosion inhibitor injection.

- pH adjustment in humidification make-up water.

Because the fluid only contacts the tubing, peristaltic pumps eliminate cross-contamination risks and simplify maintenance—both critical advantages in regulated cleanroom environments.

The strategic importance of these products in cleanroom environments can be summarized as follows:

Differential pressure and airflow monitoring prevent the ingress or escape of contaminants, safeguarding product quality.

Continuous, traceable environmental data supports compliance with GMP, ISO, and FDA standards.

Stable temperature, humidity, and pressure ensure repeatable production processes and high yield.

BLDC pumps and precise control loops reduce energy consumption in facilities known for high operational costs.

Redundant sensors and switches provide early warning and rapid response to abnormal conditions.

For cleanroom applications, the following product categories are especially critical:

- Differential Pressure Transmitters for room-to-room pressure control

- Temperature & Humidity Transmitters for environmental stability

- Environmental Transmitters for integrated monitoring

- BLDC Circulation Pumps for AHU and thermal control loops

- Diaphragm Booster Pumps for humidification and auxiliary water systems

- Peristaltic Pumps for chemical dosing and water treatment

- Flowmeters and Pressure Switches for validation and safety

Cleanrooms represent one of the most demanding application environments for pumps and sensors. Precision, stability, and reliability are not optional—they are fundamental requirements. By leveraging advanced differential pressure monitoring, accurate environmental sensing, efficient circulation pumps, and contamination-free dosing solutions, cleanroom operators can achieve robust contamination control, regulatory compliance, and long-term operational efficiency.

In an era where cleanroom standards continue to tighten and operational costs rise, the thoughtful selection and integration of these critical components provide not only technical assurance but also a strategic advantage in maintaining consistent quality and sustainable performance.