Machinery manufacturing and automation encompass a wide range of industrial activities, including production of mechanical components, assembly lines, automated equipment, CNC machining centers, and robotics integration. The key challenges in this industry are ensuring precise operation, consistent quality, energy efficiency, and equipment reliability. Any deviation in process parameters can directly affect product quality, machine longevity, and production throughput.

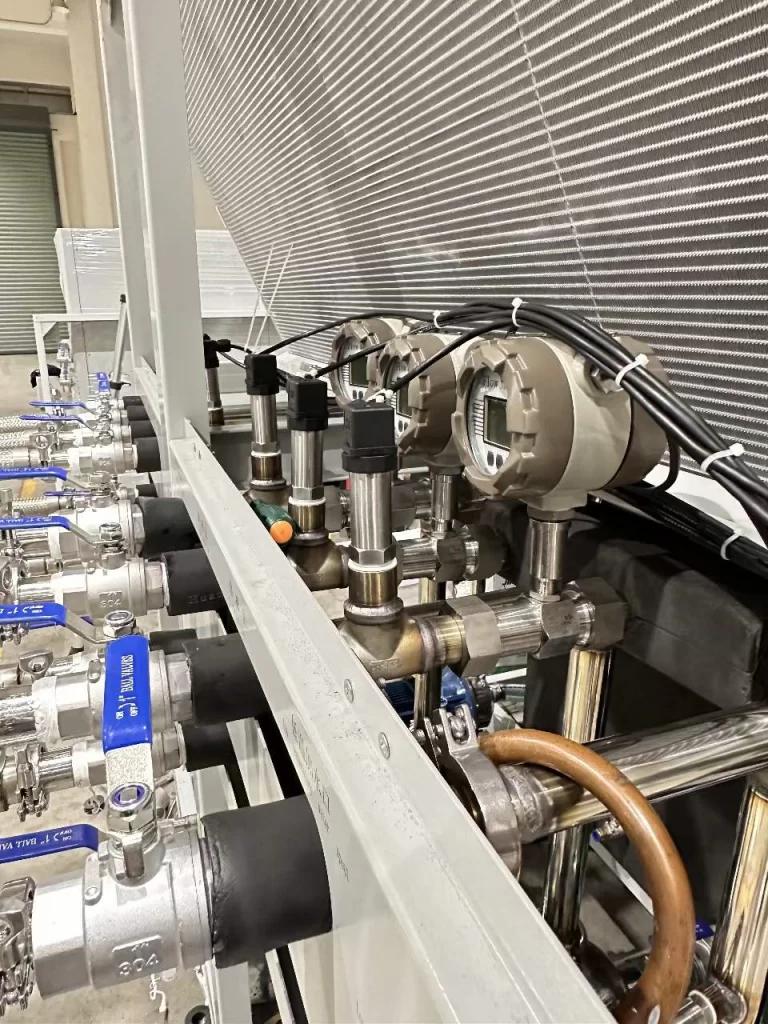

To meet these demands, core instrumentation devices such as pressure transmitters, differential pressure transmitters, pressure switches, flowmeters, and temperature & humidity transmitters are widely implemented. These devices provide real-time monitoring, accurate control, and safety functions critical to automated machinery operations.

Pressure transmitters are extensively used in hydraulic, pneumatic, and lubrication systems across machinery manufacturing plants. Their applications include:

- Monitoring hydraulic press pressures to ensure consistent force and safety

- Controlling pneumatic actuators and valves in automated production lines

- Measuring system pressure in lubrication circuits for CNC machines and robots

The advantages of pressure transmitters in this sector are significant:

- High accuracy under dynamic and fluctuating pressures

- Long-term stability for continuous operation

- Compatibility with hydraulic oils and industrial fluids

By providing precise pressure data, transmitters allow machinery to operate safely, optimize force application, and reduce wear on components.

Differential pressure transmitters are essential for monitoring pressure drops in filters, air or oil lines, and hydraulic systems. Typical applications in machinery manufacturing include:

- Detecting clogged filters in lubrication and coolant systems

- Monitoring pressure drop across heat exchangers in industrial equipment

- Balancing air supply in pneumatic networks

These devices enable predictive maintenance, preventing unexpected downtime and reducing maintenance costs. Continuous differential pressure measurement also supports process optimization, ensuring consistent performance of automated machinery.

Pressure switches serve as fail-safe protection devices in automated machinery systems. Their key functions include:

- Emergency shutdown for hydraulic and pneumatic equipment exceeding safe pressure limits

- Protection against underpressure in lubrication systems to prevent mechanical failure

- Integration with safety interlocks for automated production lines

By providing immediate, hardwired responses independent of software logic, pressure switches enhance machine reliability and operator safety.

Flowmeters are critical in monitoring and controlling the flow of hydraulic oils, coolants, and process fluids in automated machinery:

- Ensuring correct flow rates for CNC lubrication systems and cutting fluids

- Monitoring coolant circulation in injection molding and machining operations

- Supporting energy-efficient operation of hydraulic and pneumatic systems

Flowmeters contribute to operational efficiency, prevent over- or under-supply of fluids, and reduce energy consumption in production equipment.

Temperature & humidity transmitters provide vital data for both process control and equipment protection in manufacturing environments:

- Monitoring ambient conditions in production floors to prevent condensation and corrosion on sensitive machinery

- Controlling temperature of hydraulic fluids, lubricants, and cooling water

- Supporting climate-sensitive production processes such as precision machining or additive manufacturing

By ensuring stable environmental conditions, these transmitters help maintain product quality, prevent equipment degradation, and reduce maintenance requirements.

The integration of these sensors and devices provides multiple benefits for machinery manufacturing and automation:

1. Operational Safety

Pressure switches and transmitters prevent mechanical failures and protect operators.

2. Process Accuracy

Differential pressure transmitters and flowmeters ensure optimal fluid delivery and precise operation of automated systems.

3. Equipment Longevity

Real-time monitoring of pressure, flow, and temperature prevents wear, overheating, and lubricant degradation.

4. Energy Efficiency

Accurate measurement and control of hydraulic and coolant systems minimize energy consumption.

5. Predictive Maintenance

Sensor data supports early detection of system anomalies, reducing unplanned downtime.

For machinery manufacturing and automation applications, the most critical devices include:

* Pressure transmitters for hydraulic, pneumatic, and lubrication systems

* Differential pressure transmitters for filter and system monitoring

* Pressure switches for safety and fail-safe protection

* Flowmeters for hydraulic and coolant management

* Temperature & humidity transmitters for environmental and process control

In the machinery manufacturing and automation industry, precision, safety, and reliability are paramount. Pressure transmitters and differential pressure transmitters provide accurate monitoring for hydraulic and pneumatic systems. Pressure switches offer immediate protection against unsafe conditions. Flowmeters ensure proper fluid delivery, and temperature & humidity transmitters maintain stable operational environments. Together, these instruments form the backbone of modern automated manufacturing, enabling consistent product quality, operational efficiency, and long-term equipment reliability.