The oil and gas industry operates in some of the most demanding environments on earth—offshore platforms, desert fields, arctic regions, and high-pressure processing facilities. Upstream exploration, midstream transportation, and downstream refining all involve hazardous media, extreme pressures, wide temperature ranges, and continuous operation. In this context, system failures are not merely costly; they pose serious safety, environmental, and regulatory risks.

To maintain safe, efficient, and compliant operations, oil and gas facilities rely heavily on explosion-proof pressure transmitters, differential pressure transmitter, pressure switches, flowmeters, temperature sensors. Among these, pressure measurement and protection devices are of paramount importance, forming the foundation of process control, equipment protection, and emergency shutdown systems.

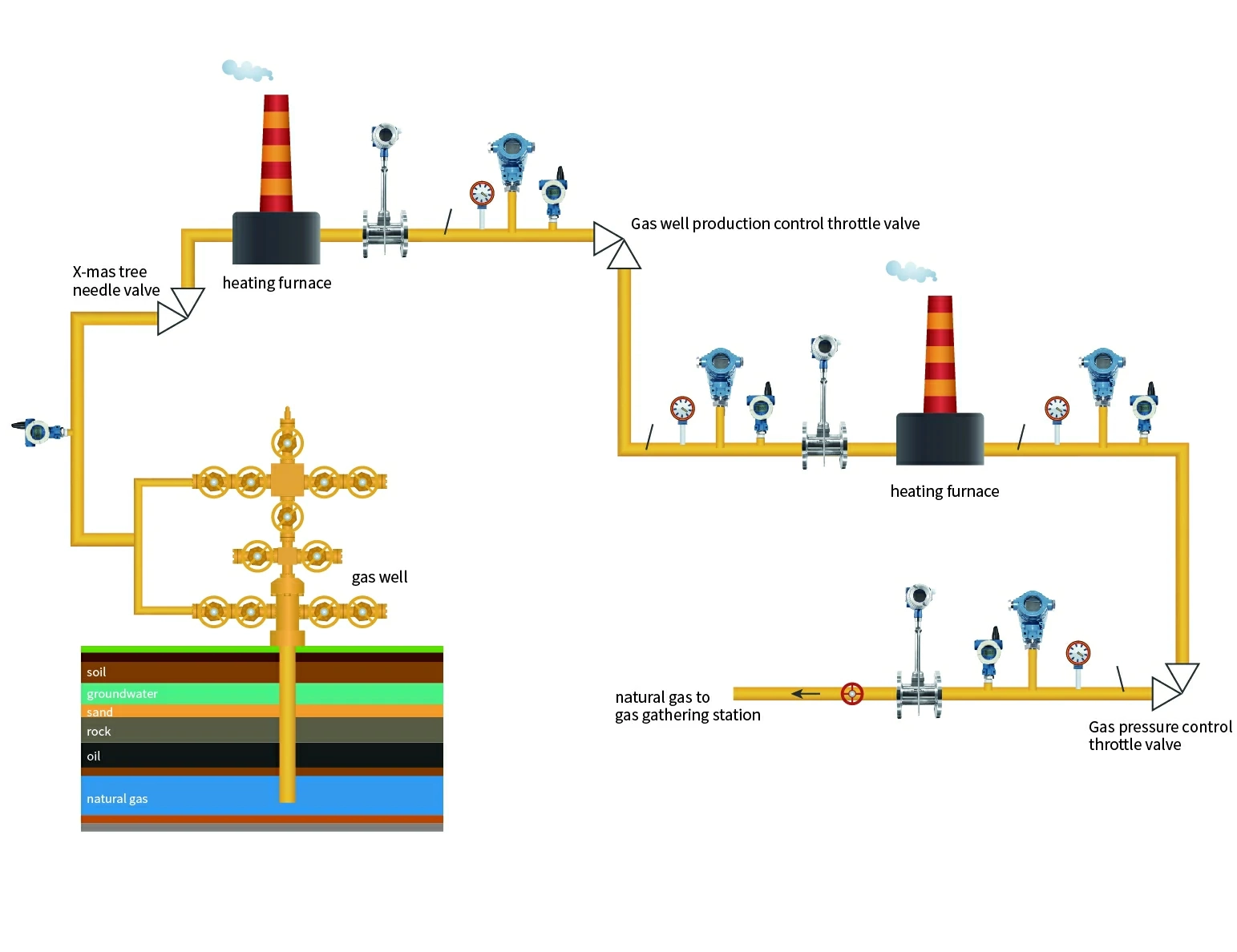

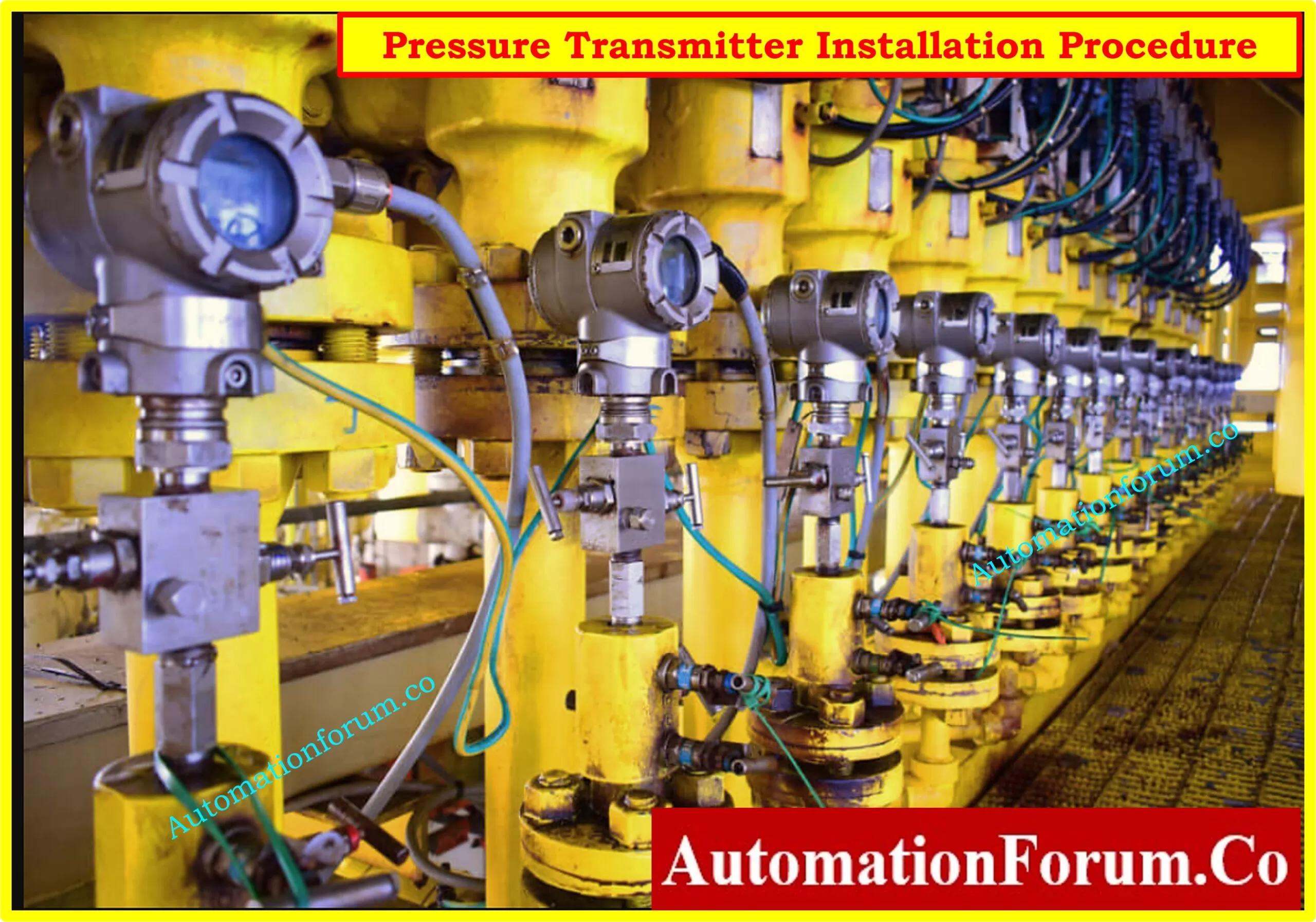

Pressure transmitters are among the most critical instruments in oil and gas operations. They provide continuous, real-time measurement of pressure in pipelines, vessels, compressors, separators, and reactors. Typical applications include:

- Wellhead pressure monitoring in upstream production

- Pipeline pressure monitoring for crude oil, natural gas, and refined products

- Separator and vessel pressure control in processing facilities

- Compressor suction and discharge pressure measurement

Accurate pressure data enables operators to maintain stable operating conditions, optimize throughput, and detect abnormal trends before they escalate into failures. In high-pressure gas systems, even small deviations can indicate leaks, blockages, or equipment degradation.

Modern oil and gas facilities rely on sophisticated control strategies implemented through DCS and SCADA systems. Pressure transmitters provide the essential input signals for:

- Flow and pressure control loops

- Anti-surge control in compressors

- Pressure balancing in multi-stage separation processes

- Energy optimization in pumping and compression systems

High-quality pressure transmitters designed for oil and gas service offer excellent long-term stability, resistance to vibration, and compatibility with aggressive hydrocarbons, ensuring reliable data in continuous operation.

While pressure transmitters support continuous control, pressure switches play a vital role in safety-critical applications. They are widely used as part of:

- Emergency shutdown (ESD) systems

- Compressor and pump protection schemes

- Overpressure and underpressure alarms

Pressure switches provide immediate, hardware-based responses when pressure exceeds or falls below predefined limits. Because they operate independently of software logic, communication networks, or power fluctuations, they are trusted as fail-safe devices in hazardous environments.

In upstream and midstream operations, pressure switches are often mandated by safety standards and regulatory frameworks as part of layered protection strategies.

Flowmeters are essential throughout the oil and gas value chain. Their applications include:

- Measuring production flow from wells

- Monitoring pipeline throughput

- Supporting custody transfer and allocation

- Verifying injection and treatment processes

Accurate flow measurement supports not only operational efficiency but also commercial accountability and regulatory compliance. In many applications, flow data is closely correlated with pressure data to validate system integrity and detect anomalies such as leaks or fouling.

Although pressure dominates system control, temperature sensors provide critical contextual information. Temperature monitoring is essential for:

- Ensuring safe operating limits in reactors and separators

- Protecting equipment from overheating or thermal stress

- Supporting accurate pressure and flow compensation

In gas processing and refining, temperature deviations can signal chemical imbalance, fouling, or heat exchanger performance issues. When integrated with pressure transmitters, temperature sensors provide a more complete picture of process conditions.

The importance of process instruments in oil and gas operations can be summarized as follows:

1. Operational Safety

Pressure switches and transmitters protect personnel, equipment, and the environment from hazardous conditions.

2. Process Reliability

Continuous monitoring ensures stable operation under extreme pressures and temperatures.

3. Regulatory Compliance

Accurate measurement and data logging support compliance with industry and government regulations.

4. Asset Protection

Early detection of abnormal conditions reduces equipment wear and prevents catastrophic failures.

5. Efficiency and Optimization

High-quality pressure and flow data enable advanced control strategies that reduce energy consumption and operational costs.

For oil and gas applications, the most critical product categories include:

* High-accuracy pressure transmitters for process monitoring

* Pressure switches for safety and emergency shutdown

* Flowmeters for process control and custody transfer support

* Temperature sensors for equipment and process protection

In the oil and gas industry, pressure is synonymous with risk, opportunity, and control. Pressure transmitters provide the continuous, accurate data required for efficient and optimized operations, while pressure switches deliver the hardwired protection necessary for safety-critical applications. Supported by flow and temperature measurement, these instruments form the backbone of modern oil and gas process control architectures.

As the industry continues to pursue higher efficiency, lower emissions, and improved safety performance, the importance of robust, reliable, and precise instrumentation will only increase. These technologies do not merely support oil and gas operations—they safeguard them.