Engineering equipment encompasses a broad range of heavy machinery used in construction, civil engineering, mining, and infrastructure development. These machines—including excavators, cranes, concrete pumps, tunnel boring machines, and hydraulic lifts—operate under extreme conditions involving heavy loads, variable pressures, and fluctuating environmental conditions. Ensuring the reliability, safety, and efficiency of these systems requires real-time monitoring and precise control.

Key devices enabling these capabilities include pressure transmitters, differential pressure transmitters, pressure switches, flowmeters, and temperature & humidity transmitters. These instruments provide critical feedback for system control, equipment protection, and operational optimization.

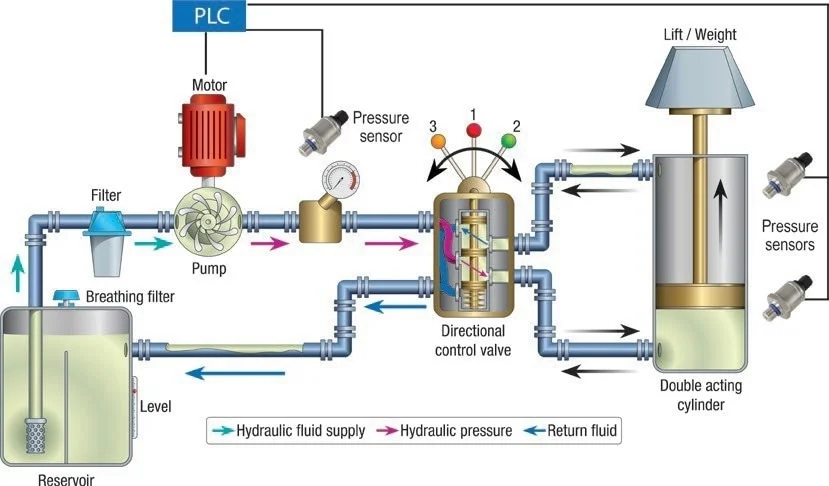

Hydraulic systems are the lifeblood of most engineering equipment. Pressure transmitters are essential for monitoring and controlling pressures in hydraulic circuits that drive motors, actuators, and pistons. Applications include:

- Monitoring boom and arm hydraulics in excavators and cranes

- Maintaining system pressure in concrete pumps and material handling equipment

- Ensuring safe operation of hydraulic lifts and loaders

High-accuracy pressure transmitters allow operators to precisely control movement and force, prevent overload, and maintain system stability even under high dynamic loads. They also feed into automated control systems for predictive adjustments and energy-efficient operation.

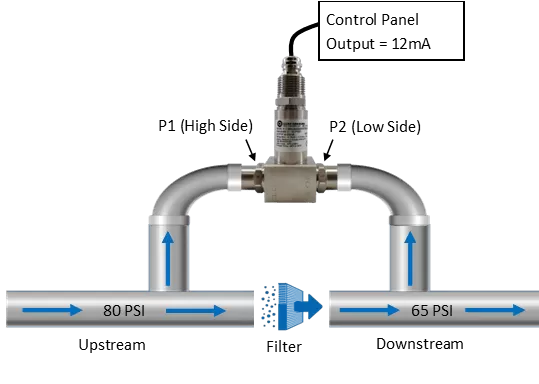

Differential pressure transmitters are used in applications where pressure differences across components need to be monitored for system performance and safety. Common uses include:

- Measuring pressure drop across hydraulic filters to detect clogging

- Monitoring pump performance and flow resistance in fluid circuits

- Balancing multi-stage hydraulic systems in heavy machinery

By continuously measuring differential pressure, these devices enable preventive maintenance, reduce the risk of sudden failures, and optimize energy consumption in hydraulic circuits.

Pressure switches act as immediate protection devices in engineering equipment. They provide:

- Emergency shutdown triggers in overpressure or low-pressure situations

- Protection for hydraulic pumps and actuators from excessive load

- Integration with interlocks to prevent unsafe machine operation

In environments where machinery operates under high stress and dynamic loads, pressure switches ensure operator safety and prevent equipment damage, serving as a critical fail-safe layer.

Flowmeters are used extensively in engineering equipment to monitor hydraulic, cooling, and lubrication fluids. Applications include:

- Measuring hydraulic oil flow to ensure precise actuator response

- Monitoring coolant circulation to prevent overheating of engines and motors

- Tracking lubricant flow in automated lubrication systems for large machinery

Accurate flow measurement allows operators to maintain optimal system performance, reduce energy consumption, and extend equipment lifespan.

Environmental factors significantly impact engineering equipment, particularly in outdoor or harsh conditions. Temperature & humidity transmitters provide:

- Monitoring of hydraulic fluid temperature to prevent overheating and viscosity loss

- Detection of ambient humidity that can cause corrosion or electrical issues

- Support for climate-sensitive operations such as tunneling or high-precision lifting

These sensors help maintain equipment integrity, improve performance reliability, and prevent downtime due to environmental damage.

The combined use of these instruments delivers several key advantages:

1. Operational Safety

Pressure switches and transmitters prevent overpressure, equipment failure, and accidents.

2. Precision Control

Differential pressure transmitters and flowmeters enable accurate actuation and movement control.

3. Equipment Longevity

Continuous monitoring of pressure, flow, and temperature reduces mechanical wear and overheating.

4. Efficiency and Energy Optimization

Real-time data supports adaptive operation, reducing fuel and hydraulic energy consumption.

5. Predictive Maintenance

Sensor data allows early detection of blockages, leaks, or abnormal conditions, minimizing downtime.

For engineering equipment applications, essential devices include:

* Pressure transmitters for hydraulic and actuator monitoring

* Differential pressure transmitters for filter and system performance

* Pressure switches for emergency protection and safety interlocks

* Flowmeters for hydraulic, coolant, and lubrication systems

* Temperature & humidity transmitters for environmental and equipment condition monitoring

In engineering equipment, reliability, precision, and safety are critical to operational success. Pressure transmitters and differential pressure transmitters provide the data necessary for controlled hydraulic operations. Pressure switches ensure fail-safe operation, while flowmeters monitor critical fluid systems for efficiency. Temperature and humidity transmitters safeguard both equipment and environmental conditions. Together, these instruments enable machinery to perform consistently under demanding conditions, improve maintenance practices, and maximize operational efficiency, forming the backbone of modern automated engineering equipment management.