The water and wastewater industry is one of the most infrastructure-intensive and mission-critical sectors in modern society. Municipal drinking water supply, industrial water treatment, sewage collection, and wastewater treatment plants must operate continuously, often under harsh environmental conditions, while meeting strict regulatory and public health requirements. System downtime, inaccurate measurement, or uncontrolled pressure fluctuations can lead to service interruptions, environmental pollution, equipment damage, or regulatory violations.

Within this demanding operational landscape, pressure transmitters, pressure switches, flowmeters, diaphragm ro booster pumps and peristaltic pumps play a decisive role. These components form the backbone of monitoring, control, and dosing systems throughout water abstraction, treatment, distribution, and wastewater processing.

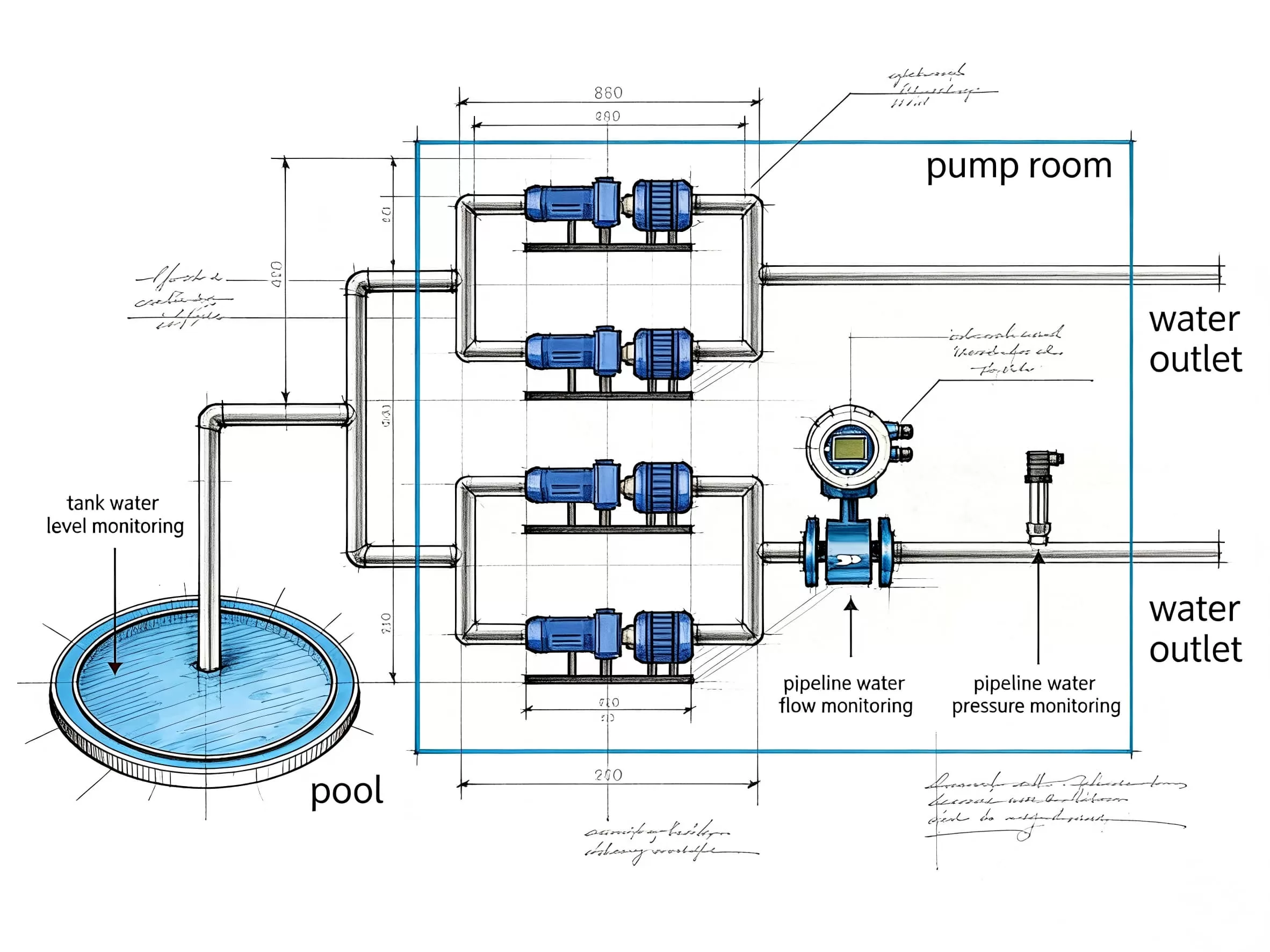

In water treatment and distribution networks, pressure stability is essential to ensure reliable delivery, prevent pipeline damage, and reduce leakage losses. Pressure transmitters are widely deployed at:

- Pump stations and booster stations

- Filtration and membrane systems

- Distribution mains and pressure zones

By continuously measuring pipeline pressure, transmitters provide real-time feedback to SCADA and automation systems. This enables operators to regulate pump speed, detect abnormal pressure drops caused by leaks or bursts, and maintain stable service pressure across wide geographic areas.

In wastewater applications, pressure transmitters are equally important in pressurized sewer systems, sludge transport lines, and anaerobic digestion processes, where pressure anomalies can indicate blockages or process instability.

While transmitters provide continuous data, **pressure switches** serve as critical safety and protection devices. Their primary functions include:

- Protecting pumps from dry running or overpressure conditions

- Providing emergency shutdown in case of pipe rupture or valve failure

- Acting as fail-safe interlocks independent of digital control systems

In water and wastewater plants, where pumps often operate unattended for long periods, pressure switches provide essential hardware-level protection that reduces the risk of catastrophic equipment failure.

Flowmeters are indispensable in both water treatment and wastewater processing. Accurate flow measurement supports:

- Raw water intake monitoring

- Treated water output verification

- Chemical dosing ratio control

- Regulatory reporting and billing

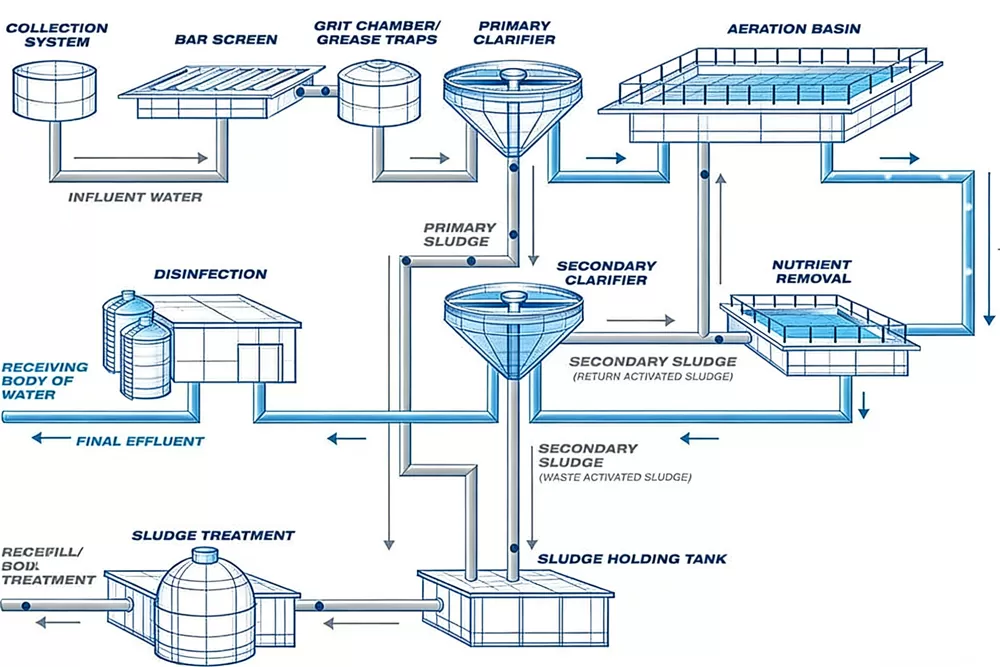

In drinking water plants, flowmeters help ensure that treatment processes such as filtration, disinfection, and reverse osmosis operate within design parameters. In wastewater treatment facilities, they are used to monitor Inflow and outflow rates, balance process stages, and verify compliance with discharge permits.

Flow data is often combined with pressure and level information to optimize pump operation and energy usage, particularly in large municipal networks.

Diaphragm booster pumps are widely used in water and wastewater facilities for applications requiring reliable pressure boosting under intermittent or variable flow conditions. Typical uses include:

- Supplying water to membrane filtration systems

- Feeding sampling and analysis equipment

- Supporting small-scale distribution or transfer tasks

Their ability to handle air-liquid mixtures, tolerate pressure fluctuations, and operate reliably in start-stop cycles makes them well suited to decentralized and auxiliary applications throughout treatment plants.

Chemical treatment is fundamental to both water purification and wastewater processing. Coagulants, disinfectants, pH adjusters, and anti-scaling agents must be dosed accurately and consistently.

Peristaltic pumps are particularly well suited for chemical dosing in this industry because:

- The fluid only contacts the tubing, minimizing corrosion and contamination

- Flow rates are highly repeatable and easy to adjust

- Maintenance is simple and predictable

Typical dosing applications include:

- Chlorine or sodium hypochlorite injection

- pH correction using acids or alkalis

- Nutrient dosing in biological wastewater treatment

Precise dosing supported by flow measurement and pressure monitoring ensures treatment efficiency while reducing chemical waste and environmental impact.

The importance of these pumps and sensors in the water and wastewater industry can be summarized as follows:

1. Operational Reliability

Continuous pressure and flow monitoring ensures uninterrupted service and early fault detection.

2. Energy Efficiency

Variable-speed pumps combined with accurate sensing significantly reduce energy consumption.

3. Process Stability

Precise control of pressure, flow, and chemical dosing improves treatment effectiveness.

4. Equipment Protection

Pressure switches and transmitters prevent damage to pumps, pipes, and treatment units.

5. Regulatory Compliance

Accurate measurement and data logging support reporting and environmental compliance.

For water and wastewater applications, the most critical product categories include:

* Pressure transmitters for pipeline and pump station monitoring

* Pressure switches for pump protection and emergency shutdown

* Flowmeters for treatment process control and compliance

* Diaphragm booster pumps for auxiliary pressurization

* Peristaltic pumps for chemical dosing and treatment control

Water and wastewater systems operate under constant pressure—both literally and figuratively. They must deliver reliable service, protect public health, and meet stringent environmental regulations while controlling operational costs. In this context, pumps, pressure sensors, flowmeters, and dosing equipment are not merely supporting components; they are fundamental enablers of safe, efficient, and sustainable water infrastructure.

By integrating reliable pressure monitoring, intelligent pump control, accurate flow measurement, and precise chemical dosing, water and wastewater operators can achieve higher system resilience, improved energy performance, and long-term regulatory compliance. As global demand for clean water and effective wastewater treatment continues to rise, the strategic importance of these technologies will only become more pronounced.