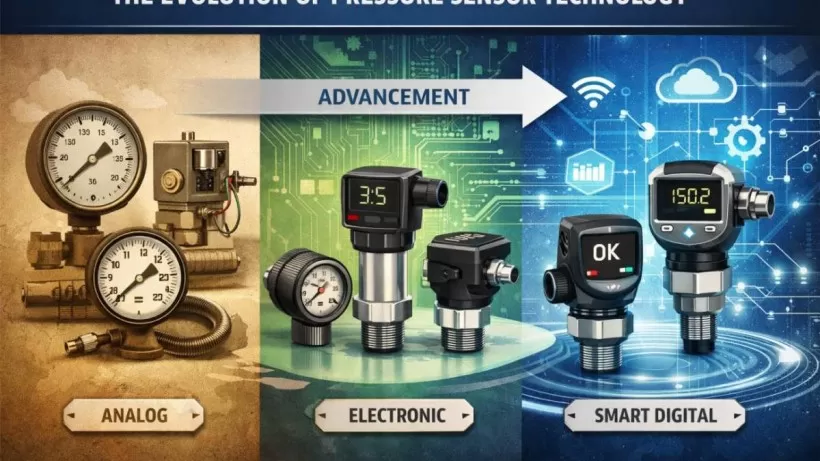

Pressure sensors are among the most widely used instruments in industrial automation and control systems. For decades, they have served as the foundation of safe and efficient operations across manufacturing, HVAC, water treatment, and countless other sectors. However, pressure sensor technology has evolved dramatically — transitioning from basic mechanical devices to highly advanced digital pressure transmitters that enable smart, data-driven monitoring.

As industries move toward greater automation and connectivity, understanding this evolution is key to appreciating how modern sensors, like those developed by Lefoo, are shaping the future of industrial measurement and control.

The first generation of pressure sensors relied entirely on mechanical principles. These analog pressure gauges and mechanical switches used elements like Bourdon tubes, diaphragms, or bellows to convert pressure into physical movement, which was then displayed on a dial or used to open or close electrical contacts.

While robust and simple, analog devices had limitations. They provided only local readings, were prone to wear, and offered limited accuracy compared to today's standards. Calibration drift and mechanical fatigue often required frequent maintenance — especially in environments with vibration, temperature variation, or contamination.

Analog pressure switches were suitable for basic on/off control, but they lacked the ability to transmit data or integrate with automation systems. As industrial operations became more complex, the need for more precise, electronic-based measurement grew rapidly.

The next phase in pressure sensor technology began with the introduction of electrical sensing elements, particularly piezoresistive sensors. These devices used semiconductor materials whose resistance changed when subjected to pressure.

This advancement allowed pressure to be converted into an electrical signal — a major leap forward for process control. Electrical output could now be transmitted over distances, integrated into feedback loops, and recorded for monitoring and analysis.

During this period, pressure sensors became smaller, faster, and more accurate. However, they still relied heavily on analog signal transmission, which was susceptible to electrical noise and signal degradation in long-distance communication.

With the rise of microelectronics and digital technology, pressure measurement entered a new era. Digital pressure transmitters combined the precision of electrical sensing with the intelligence of onboard microprocessors. These devices not only measured pressure but also converted it into digital signals that could be easily processed and transmitted to control systems such as PLCs, SCADA, or IoT platforms.

Unlike analog sensors, digital transmitters provide multiple advantages:

Higher accuracy and resolution due to digital signal processing.

Noise immunity for stable readings even in electrically noisy environments.

Programmable parameters such as range, units, and response time.

Diagnostic capabilities for maintenance and troubleshooting.

Digital communication protocols like Modbus, CAN, or I²C for easy integration.

Lefoo digital pressure transmitters, for example, feature advanced microprocessors that ensure precise data acquisition and transmission, supporting both analog (4–20 mA, 0–10 V) and digital outputs for maximum flexibility.

Today, the evolution continues with the integration of smart sensors and Industrial IoT (IIoT) technologies. Modern Lefoo pressure sensors are no longer just measuring devices — they are intelligent data nodes that communicate with centralized systems, providing real-time insights and predictive analytics.

These smart pressure monitoring systems enable:

Remote access: Engineers can view live data from any location.

Predictive maintenance: Continuous monitoring detects performance trends before failures occur.

Data logging: Historical data helps optimize process parameters.

Automated control: Systems automatically adjust pumps or valves based on sensor feedback.

Energy optimization: Efficient operation through precise, adaptive control.

By combining sensing accuracy with digital intelligence, Lefoo's solutions help industries move from reactive maintenance to proactive, data-driven operations — the hallmark of modern automation.

Microcontrollers have transformed how sensors are designed and maintained. In traditional analog systems, calibration required manual adjustment. In modern digital sensors, calibration can be performed electronically or even remotely through software interfaces.

Lefoo's high-precision digital pressure transmitters feature built-in temperature compensation, ensuring stable performance even under fluctuating environmental conditions. Additionally, their self-diagnostic features detect issues such as drift, overload, or short circuits, simplifying maintenance and ensuring long-term reliability.

These innovations reduce downtime and total cost of ownership while improving safety and compliance in critical applications.

The versatility of modern pressure sensors makes them indispensable in a wide range of industries:

HVAC Systems: Real-time refrigerant and air pressure monitoring for efficiency and environmental compliance.

Water Treatment Plants: Maintaining stable flow and filtration pressures.

Industrial Automation: Regulating hydraulic and pneumatic systems for precision manufacturing.

Energy and Oil & Gas: Monitoring high-pressure pipelines and ensuring safety in hazardous areas.

Medical Devices: Measuring air and fluid pressure in life-support and diagnostic equipment.

In all these fields, Lefoo pressure sensors provide accurate, stable, and reliable measurement performance tailored to specific industrial needs.

As industries embrace Industry 4.0, the future of pressure sensor technology lies in full connectivity and sustainability. Sensors will not only measure but also learn — using artificial intelligence and machine learning to predict trends, reduce waste, and optimize resource consumption.

Lefoo continues to invest in R&D to create smarter, more energy-efficient sensors that integrate seamlessly with digital ecosystems. These innovations will enable manufacturers to achieve higher productivity while meeting global sustainability and safety standards.

From simple mechanical gauges to intelligent digital transmitters, pressure sensor technology has evolved into a cornerstone of modern industrial automation. This transformation has unlocked new levels of accuracy, control, and efficiency, empowering industries to operate smarter and more sustainably.

With its commitment to innovation, precision, and reliability, Lefoo remains at the forefront of this evolution — providing high-performance pressure sensors and digital transmitters that drive the next generation of industrial intelligence.