In every industrial process, accuracy is not just a desirable feature—it's a requirement. Whether it's controlling pressure in an HVAC system, monitoring water levels in a treatment plant, or regulating air flow in a compressor, precise sensor data ensures efficiency, safety, and quality. Over time, however, even the most advanced sensors and switches can drift from their original calibration.

Calibration is the process of verifying and adjusting the accuracy of a measurement device compared to a known reference. Regular calibration guarantees that Lefoo pressure switches, transmitters, and sensors continue to deliver reliable data, maintaining consistency and compliance with industry standards.

This article explains why calibration matters, outlines step-by-step calibration procedures, and provides best practices for keeping Lefoo equipment performing at its best.

Calibration ensures that measurement devices remain within acceptable accuracy limits throughout their operational life. Without it, even small deviations can lead to large-scale inefficiencies or safety issues.

Accuracy and reliability: Ensures that pressure readings reflect actual conditions.

Compliance: Many industries require traceable calibration to ISO or national standards.

Safety: Incorrect pressure readings can lead to system overpressure or equipment failure.

Energy efficiency: Proper calibration prevents overuse of pumps or compressors.

Process optimization: Stable readings improve control and consistency in production.

Even high-quality devices like Lefoo transmitters and switches experience natural drift due to aging, environmental stress, or vibration. Routine calibration is the best way to counteract these effects.

The ideal calibration interval depends on several factors:

| Equipment Type | Recommended Interval | Influencing Factors |

| Pressure Switch | Every 6–12 months | Operating cycles, temperature variation |

| Pressure Transmitter | Every 12 months | Environmental conditions, system criticality |

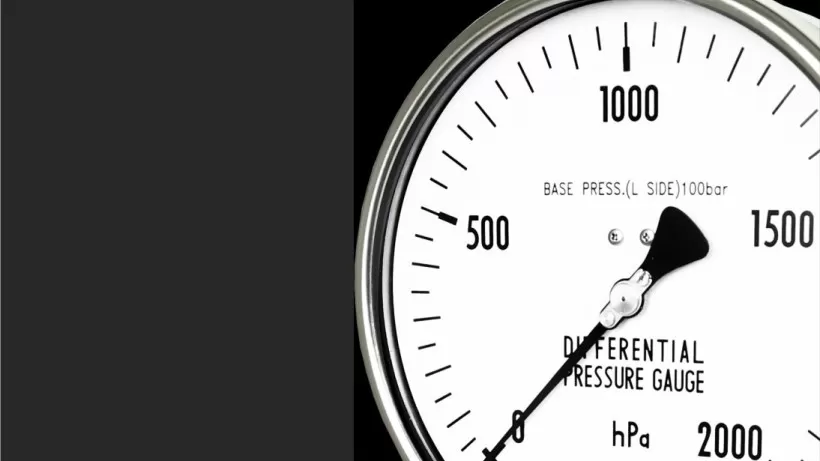

| Differential Pressure Sensor | Every 6 months | Vibration, contamination |

| Pump System (with sensor feedback) | Every 12 months | Flow stability, service load |

If a sensor operates in harsh environments—such as high humidity, temperature extremes, or chemical exposure—shorter calibration intervals are recommended.

Lefoo devices are designed for long-term stability, but keeping a regular calibration schedule maximizes performance and reduces long-term maintenance costs.

Before starting calibration, ensure that all tools and instruments are available and certified.

You will need:

A calibrated reference pressure source (deadweight tester or pressure calibrator)

A digital multimeter (for transmitters with electrical output)

Appropriate fittings and adapters compatible with the Lefoo device

Power supply or signal simulator for transmitters (typically 24 VDC)

Data recording software or sheet for logging calibration results

Manufacturer documentation with the device's nominal range and output specifications

Always verify that the reference equipment itself has been recently calibrated and certified traceable to national standards.

Pressure transmitters convert pressure into an electrical signal, typically 4–20 mA or 0–10 V. The following procedure applies to most Lefoo transmitters:

Isolate the transmitter from the process.

Clean the sensor port to remove contaminants or moisture.

Connect the transmitter to the pressure calibrator and power supply.

Let it stabilize for at least 5 minutes at ambient temperature.

Apply pressure in five ascending steps: 0%, 25%, 50%, 75%, and 100% of the full-scale range.

Record the output signal at each step.

Repeat in descending order to check hysteresis (difference between rising and falling values).

Compare measured outputs with expected values.

If deviation exceeds the manufacturer's tolerance (typically ±0.25% or ±0.5% of full scale), perform adjustment:

For analog models: use the zero and span trim screws.

For digital models: connect to the calibration software or handheld communicator to enter new calibration values.

Re-test the entire range after adjustment.

Confirm that all points fall within the accuracy specification.

Record results in a calibration certificate with date, technician name, and reference equipment used.

Pressure switches operate based on mechanical activation points rather than continuous signal output. Here's how to calibrate Lefoo pressure switches properly:

Disconnect the switch from the system.

Connect it to a regulated pressure source with a precision gauge.

Attach an electrical tester (continuity meter or indicator light) to the switch terminals.

Slowly increase pressure until the switch activates (contacts change state).

Note the activation pressure (cut-out point).

Gradually decrease pressure until it resets — this is the cut-in point.

Use the adjustment screw or knob to fine-tune the activation point according to the desired pressure range.

For dual-stage or differential switches, set both cut-in and cut-out pressures accordingly.

Repeat the test three times to ensure repeatability.

Verify that activation and reset pressures remain within tolerance limits.

Document final values for traceability.

Tip: Avoid applying rapid pressure changes, as mechanical switches need time to stabilize between readings.

Some Lefoo pumps integrate pressure or flow control sensors. In these cases, calibration ensures that the pump maintains consistent performance under load.

Connect a pressure gauge to the pump outlet.

Start the pump and allow it to reach steady operation.

Adjust internal control parameters (if accessible) or pressure setpoints.

Verify that output matches design pressure within ±5%.

Log calibration data for quality control.

To ensure consistent and repeatable calibration results, follow these professional practices:

Calibrate in controlled conditions: Maintain stable temperature and humidity in the calibration area.

Avoid mechanical stress: Do not overtighten fittings or expose the sensor to sudden pressure surges.

Use clean, dry media: Contaminated air or fluid can damage the sensing diaphragm.

Document everything: Record all results, including deviations, adjustments, and calibration references.

Train technicians regularly: Proper calibration requires both skill and understanding of measurement principles.

Seal and label calibrated devices: Mark each unit with calibration date and due date for easy tracking.

By implementing these best practices, operators can guarantee long-term reliability for their Lefoo equipment and maintain compliance with quality management systems such as ISO 9001 and ISO/IEC 17025.

Even experienced technicians sometimes make errors that can affect accuracy. Avoid the following:

Calibrating with uncertified reference instruments

Ignoring stabilization time before taking readings

Skipping zero-point verification

Applying incorrect pressure media (e.g., water in air-calibrated sensors)

Forgetting to log or archive calibration data

Consistency is the foundation of quality calibration. Following standardized methods ensures traceability and reliability across the entire production line.

Calibration is a critical part of maintaining industrial performance and safety. For every Lefoo pressure switch, transmitter, or pump, accurate calibration guarantees optimal performance, minimal downtime, and full compliance with technical standards.

By following structured procedures, using certified reference instruments, and keeping detailed records, technicians ensure that Lefoo equipment continues to operate with the precision it was designed for. Regular calibration is not just maintenance — it's an investment in reliability, energy efficiency, and process excellence.