Pressure switches are among the most widely used components in the entire industry. Developed in various configurations, the pressure switches have captive applications, designs where their characteristics are already known and crucial for the operation of the entire system.

However, by analyzing the characteristics of a pressure switch it is possible to expand its application area, creating solutions for other situations in the industry. One such application is linked to systems using filters.

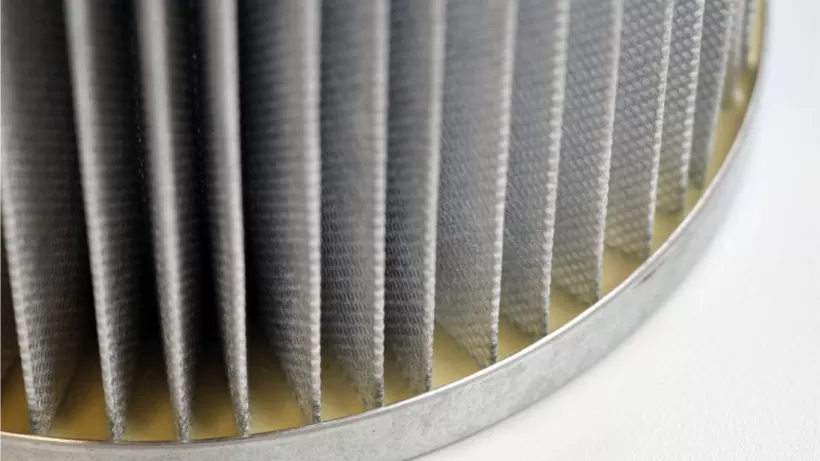

Air conditioning systems are an example of this. Filters have the function of capturing undesirable particles present in the system. Despite its importance, the presence of a filtering element in the system tends to function as a barrier to the free circulation of air. This impediment, although unwanted, is part of the system and is taken into account at the time of system planning.

However, the accumulation of debris in the filter tends to increase its resistance to air circulation, reducing the efficiency of chilled air circulation and, consequently, increasing energy consumption in an attempt to compensate for this loss. The presence of pressure switches in the system makes it possible to monitor air pressure at various points in the pipeline, identifying the pressure drop at a given point, pointing to possible obstructions and the need to change the filter element.

This same principle can be applied to various hydraulic and pneumatic systems, with considerable savings both in energy consumption and in eliminating premature system element changes.

Lefoo has a technical development center in Brazil, contributing companies from various segments in the development of customized projects that generate savings and competitive advantages. Contact Lefoo and learn more.